Globally Harmonized System (GHS): Chemical Safety Standards Explained

Welcome to Secure Waste! We are thrilled to be your trusted partner in managing Healthcare hazardous waste! With a strong focus on safety, we specialize in the responsible handling of chemicals, ensuring dangerous materials are handled in accordance with the highest compliance standards. As a leading provider in the region, we’re proud to support healthcare facilities across Maryland, Virginia, and Washington, D.C. with customized solutions designed to tackle their unique challenges.

Our dedication to excellence doesn’t stop at local service – we collaborate with international partners to implement best practices and innovative strategies in hazardous waste management. This global perspective empowers us to make a difference, contributing to a healthier, safer environment for both our communities and our planet!

We recognize that hazardous waste disposal can be complex, but our enthusiastic and knowledgeable team is here to help guide you every step of the way. If you have any questions or need any help, please feel free to contact us at 877-633-7328. At Secure Waste, your safety and peace of mind are our top priorities, and we can’t wait to work together!

Need a Biohazard pick up? More Here.

In todays world understanding chemical safety standards is crucial for protecting human health and the environment These standards provide essential guidelines for handling storing and disposing of hazardous materials Secure waste management practices ensure that potentially dangerous substances are treated responsibly minimizing risks and enhancing safety This thorough exploration of chemical safety standards highlights the importance of secure waste practices in preventing accidents promoting sustainability and safeguarding our communities

Globally Harmonized System (GHS): An Explanation of Chemical Safety Standards

Staying current with chemical safety regulations is essential for healthcare organizations, laboratories, manufacturing environments, and any workplace that handles hazardous substances. Regulatory compliance not only protects employees but also reduces liability, prevents accidents, and ensures uninterrupted operations. One of the most essential frameworks supporting chemical safety worldwide is the Globally Harmonized System of Classification and Labeling of Chemicals (GHS). This system provides a standardized approach to identifying chemical hazards and communicating risks clearly and consistently.

The Globally Harmonized System was developed to address inconsistencies in chemical classification and labeling across countries. Before its adoption, chemical hazard communication varied widely, leading to confusion and increased risk of misinterpretation. GHS establishes uniform criteria for classifying chemical hazards and mandates consistent labeling elements and Safety Data Sheets to ensure workers understand the risks associated with the chemicals they handle.

How GHS Aligns With Hazard Communication Requirements

In the United States, GHS is incorporated into the Occupational Safety and Health Administration’s Hazard Communication Standard. This alignment ensures that workers receive clear, standardized information about chemical hazards regardless of where the chemical originates. Under this framework, manufacturers and employers share responsibility for ensuring that hazardous chemicals are correctly classified, labeled, and documented.

Every hazardous chemical in the workplace must have an accompanying Safety Data Sheet that follows a standardized 16-section format. This format ensures consistency and allows employees to quickly locate critical information related to chemical composition, health effects, safe handling practices, and emergency response measures. Labels must also include standardized elements such as signal words, hazard statements, precautionary statements, and pictograms.

The Importance of Accurate Chemical Classification

Accurate classification is the foundation of effective hazard communication. Chemicals must be evaluated for physical, health, and environmental hazards, where applicable. Physical hazards include flammability, explosiveness, and reactivity. Health hazards encompass acute toxicity, carcinogenicity, respiratory sensitization, and other long-term health effects. Proper classification ensures that employees receive the appropriate warnings and protective measures.

When chemical hazards are misclassified or overlooked, workers may unknowingly expose themselves to dangerous conditions. Accurate classification reduces guesswork and supports safer handling, storage, and disposal practices across all departments.

Safety Data Sheets as a Cornerstone of Chemical Safety

Safety Data Sheets serve as comprehensive references on chemical hazards and safe work practices. Employers are required to maintain accessible SDSs for every hazardous chemical in use. Employees must be able to review these documents during their work shift without barriers.

The standardized SDS format improves usability by organizing information into predictable sections, including hazard identification, first-aid measures, fire-fighting measures, accidental release procedures, and exposure controls. This structure allows employees and emergency responders to identify critical safety information when it matters most quickly.

Understanding Chemical Labels and Pictograms

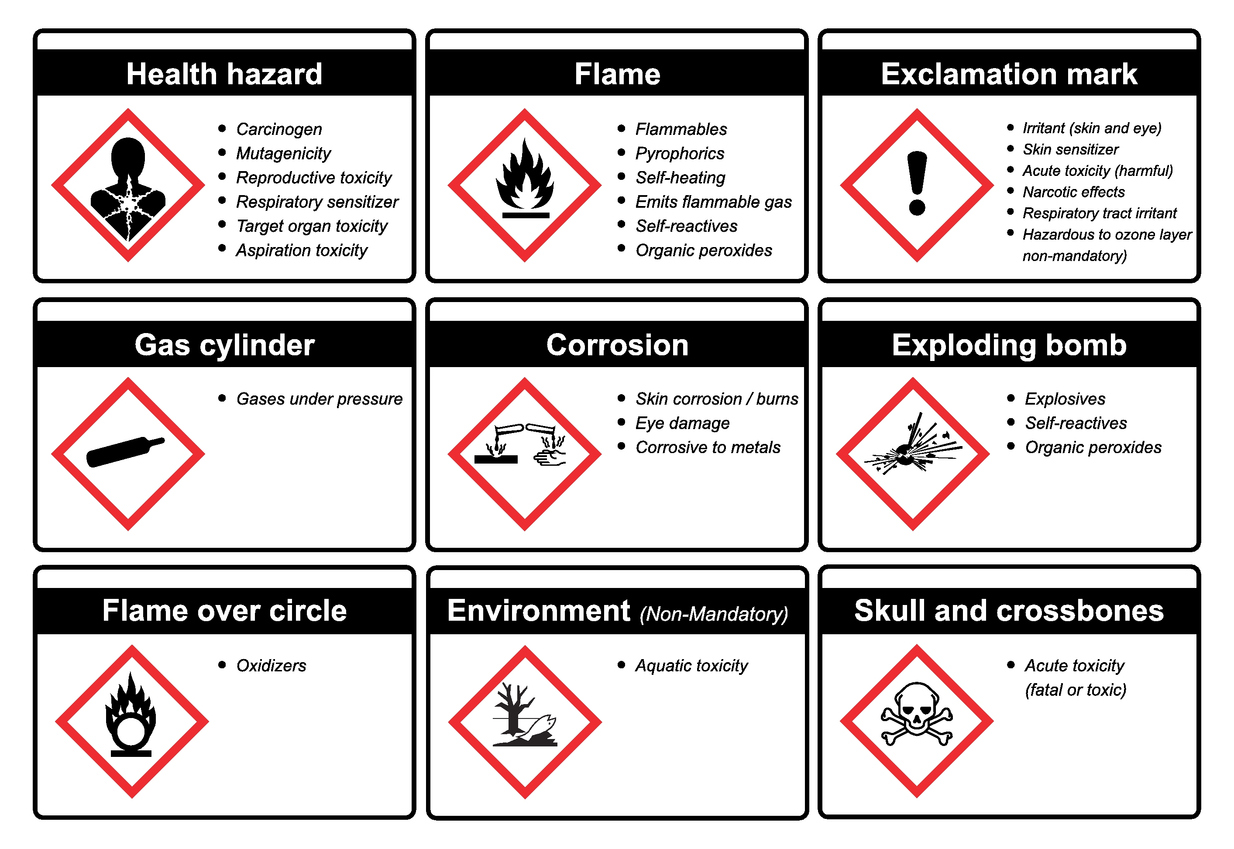

Chemical labels play a vital role in daily workplace safety. GHS labels include standardized pictograms that visually communicate hazard types at a glance. These symbols represent hazards such as flammable materials, corrosive substances, toxic chemicals, and health risks. When combined with clear signal words and hazard statements, pictograms provide an immediate warning even before the SDS is consulted.

Employees must be trained to accurately recognize and interpret these pictograms. Misunderstanding a symbol can lead to improper handling, storage errors, or inadequate use of personal protective equipment.

Training Requirements Under GHS

Training is a critical component of GHS compliance. Employees must understand how to read and interpret chemical labels, pictograms, and Safety Data Sheets. Training should cover manufacturer label requirements, the meanings of pictograms, and the structure of the revised SDS format.

Practical training ensures that employees are not only aware of chemical hazards but also confident in applying safety procedures. Training should occur during onboarding, whenever new chemicals are introduced, and periodically thereafter to reinforce knowledge and address regulatory updates.

Maintaining Compliance Over Time

GHS compliance is not a one-time task. As regulations evolve and new chemicals enter the workplace, organizations must reassess their hazard communication programs. Safety Data Sheets should be reviewed and updated when new information becomes available. Labels must remain legible and accurate, and training records should be maintained to demonstrate compliance.

Routine audits help identify gaps in documentation, labeling, or employee understanding. These reviews provide an opportunity to correct issues before they result in incidents or regulatory findings.

The Role of Leadership and Workplace Culture

Leadership commitment plays a significant role in the success of chemical safety programs. When management prioritizes compliance and safety, employees are more likely to follow procedures and report concerns. Clear policies, accessible resources, and open communication reinforce a culture in which safety is a shared responsibility.

Organizations that integrate GHS principles into daily operations experience fewer chemical-related incidents and demonstrate a proactive approach to worker protection.

Final Thoughts on GHS Compliance

The Globally Harmonized System of Classification and Labelling of Chemicals is a powerful tool for improving workplace safety through clarity and consistency. By standardizing chemical classification, labeling, and documentation, GHS reduces confusion and empowers employees to work safely around hazardous substances. Organizations that invest in proper classification, accurate Safety Data Sheets, clear labeling, and comprehensive training not only meet regulatory requirements but also create safer, more resilient workplaces.

Maintaining compliance requires ongoing attention, but the benefits are substantial. A well-executed GHS program protects employees, supports operational efficiency, and strengthens organizational accountability in an increasingly regulated environment.

Expert Medical Waste Management: With over 25 years of industry experience, Secure Waste is a trusted local leader in hazardous and biohazardous waste disposal across Maryland, Virginia, and Washington, D.C. Specializing in medical waste management, sharps needle disposal, and biohazard waste removal, the company ensures full compliance with federal, state, and local regulations while prioritizing environmental sustainability.

The company also offers additional services, including secure document shredding and sharps container sales, providing comprehensive solutions for healthcare facilities and businesses. Our cost-effective services help clients maintain regulatory compliance without unexpected costs.

With a commitment to customer satisfaction, Secure Waste offers tailored waste management plans that align with industry best practices. Their team of experts provides reliable, timely, and compliant services, making them the preferred choice for medical waste disposal. For a free waste quote or more information, visit www.securewaste.net