Medical Waste Disposal & Sustainable Plastic Recycling – Expert Solutions For Healthcare Providers From Secure Waste

Healthcare facilities generate large volumes of plastic waste from disposable instruments, sterile packaging, protective gear, and numerous single-use medical devices, including sharps needles and containers, which have become standard in modern healthcare delivery. The sheer quantity of plastic used daily in hospitals, clinics, surgical centers, and other healthcare settings is staggering, with estimates suggesting healthcare facilities produce millions of tons of plastic waste annually. Managing this waste sustainably is essential for environmental stewardship and operational efficiency; however, only about 5% of healthcare plastics are currently recycled, representing a significant missed opportunity for waste reduction and cost savings. Where does medical waste go after treatment? You can learn more here.

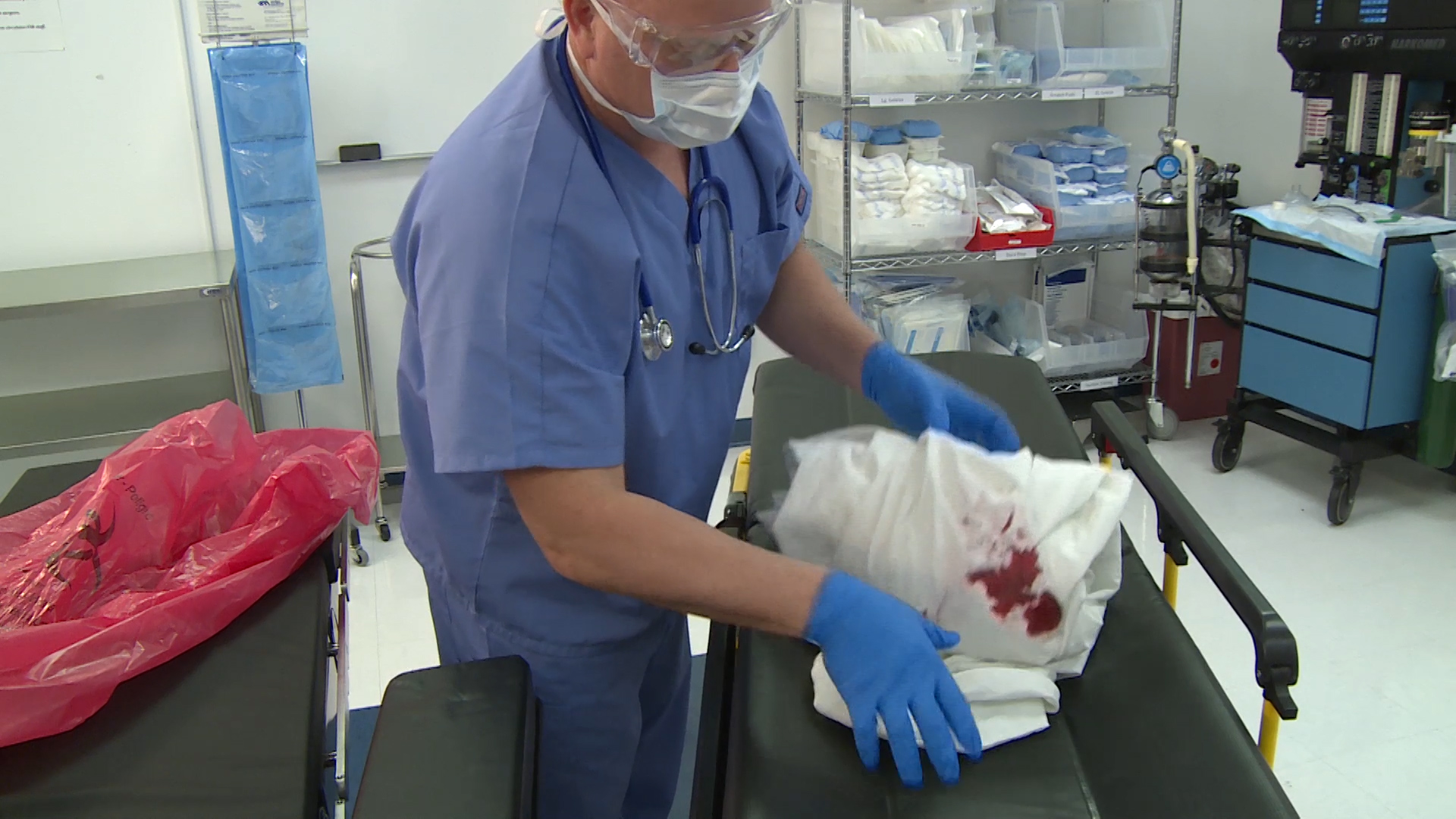

Effective healthcare waste management must balance critical patient safety priorities, secure waste removal that prevents contamination and exposure, and comply with regulatory requirements such as OSHA and HIPAA, while also achieving ambitious environmental goals that reduce the healthcare sector’s ecological footprint. The challenge lies in maintaining the highest standards of infection control and patient safety while simultaneously pursuing sustainability. Reusing and recycling plastics reduces landfill impact, conserves natural resources, decreases greenhouse gas emissions, and lowers disposal costs, all while ensuring safe and compliant disposal that protects workers, patients, and communities.

Sustainable Practices for Medical Waste Disposal

Hospitals and clinics generate vast quantities of plastic waste, which drives up operational costs and contributes significantly to healthcare’s environmental footprint. A 2025 report found that healthcare plastics generated 4.3 million metric tons of carbon dioxide-equivalent emissions through production, use, and disposal. Yet, less than 5% of these materials are diverted to recycling programs. This low recycling rate represents both an environmental problem and an economic inefficiency. In the U.S., roughly 90% of plastic trash still ends up in landfills, where it will persist for centuries, or in incinerators, where it releases emissions, rather than being recycled into new products.

By contrast, recycling plastic significantly reduces energy consumption and environmental impact compared to producing virgin plastic. One comprehensive study showed that the mechanical recycling of PET (polyethylene terephthalate, commonly used in beverage bottles and some medical containers) can use up to 79% less energy than manufacturing new plastic from petroleum feedstocks. This energy savings translates directly to reduced greenhouse gas emissions and lower operational costs. Adopting EPA-backed national recycling goals, which aim for a 50% recycling rate by 2030, requires healthcare facilities to significantly divert more plastic from waste streams through improved segregation, staff education, and infrastructure investments.

In fact, one progressive health system shifted thousands of pounds of clean plastic into recycling programs and found it cost only half as much as traditional disposal through incineration or landfilling. These sustainable waste practices not only meet environmental targets and corporate social responsibility commitments, but also save substantial money that can be redirected to patient care, reduce the facility’s carbon footprint and environmental impact, and demonstrate leadership in healthcare sustainability.

Common Healthcare Plastics

Many medical devices and supplies are made of recyclable plastics that can be diverted from waste if correctly identified and segregated. Understanding the types of plastics commonly used in healthcare helps staff make informed sorting decisions. Common types include:

Sterilization wrap: Non-woven polypropylene (PP, labeled with recycling code #5), used extensively for surgical packs and wrapping sterile instruments. This “blue wrap” is ubiquitous in operating rooms and represents a significant volume of plastic waste. While technically recyclable, concerns about contamination and a lack of processing infrastructure have historically limited the recycling of this material.

IV solution and irrigation bottles: Rigid polypropylene or high-density polyethylene (HDPE, labeled #2 or #5) containers for saline, irrigation fluids, disinfectants, and other liquids. These durable containers are often clean after use and highly suitable for recycling if properly emptied and segregated.

Basins, pitchers, and trays: Hard polypropylene or similar rigid plastic items (labeled #5) used throughout patient care areas. These items are frequently clean or minimally contaminated and can be recycled if not exposed to blood or body fluids.

Surgical packaging (Tyvek): Durable high-density polyethylene film (labeled #2) used in sterile pouches for surgical instruments and implants. Tyvek is a specialized material with unique properties, and some manufacturers have established take-back programs specifically for this material.

Transparent film and bags: Polyethylene (PE, labeled #2 or #4) used for protective sleeves on equipment, packaging for sterile items, and various containment purposes. These thin films are lightweight but represent significant volume in waste streams.

Knowing these categories helps staff sort plastics correctly at the point of generation, which is critical for successful recycling. Most hospitals have established recycling programs for bottles and rigid containers labeled #1 and #2, which municipal recycling facilities widely accept. Other plastics, such as film wraps and non-recyclable materials like PVC (polyvinyl chloride) or polystyrene, require special handling or must be disposed of as waste due to a lack of recycling infrastructure.

Challenges in Recycling Medical Plastics

Recycling plastics in healthcare is substantially more complex than curbside residential recycling programs due to the unique challenges of healthcare. Infection-control concerns and strict contamination limits often prevent plastics from being included in recycling streams, even when the material type is technically recyclable. Healthcare facilities must maintain the highest safety standards, and any uncertainty about contamination typically results in items being treated as waste rather than recyclables.

For example, surgical “blue wrap” (polypropylene sterilization wrap) can account for approximately 20% of operating room waste by volume but is notoriously difficult to recycle despite being made from recyclable plastic. The barriers include concerns about potential contamination from surgical procedures, lack of convenient collection and processing infrastructure, and costs associated with specialized handling. Regulators and recycling facilities typically allow only 0.5% contamination in recycled medical plastics, an extremely stringent standard. Even small amounts of blood, tissue, or debris mean an entire batch fails recycling standards and must be rejected, resulting in contaminated loads being sent to landfills or incinerators.

Moreover, a large share of healthcare plastic is classified as regulated medical waste subject to federal and state disposal rules that prioritize safety over sustainability. These regulations often require incineration or autoclaving (steam sterilization) for infectious waste, precluding recycling entirely. In practice, most low-risk or residual healthcare plastics are disposed of in landfills. At the same time, items that are infectious, contaminated, or potentially hazardous are destroyed through heat treatment, either by autoclaving or incineration. Changing this pattern requires careful sorting at the source to identify clean plastics before they become mixed with contaminated materials.

Infrastructure represents another significant hurdle to healthcare plastic recycling. Many U.S. hospitals, particularly those in rural areas or smaller communities, lack access to local recycling facilities that can process specialty medical plastics, such as sterilization wrap or Tyvek. Standard municipal recycling programs may not accept these materials due to liability concerns or lack of end markets. These infrastructure gaps mean that without dedicated programs and committed partnerships with specialized recyclers, much medical plastic waste ends up being disposed of rather than recycled, regardless of the facility’s intentions.

Implementing Sustainable Plastic Recycling

Despite these substantial obstacles, innovative hospitals and health systems are finding effective ways to recycle healthcare plastics, demonstrating that sustainability and safety can coexist. A critical first step is segregating clean plastics from regulated medical waste at the point of generation. This requires providing separate containers, clear visual cues through color coding and signage, and staff education about what can be safely recycled.

For instance, Spectrum Health implemented a comprehensive program that educated staff about plastic recycling and set up dedicated collection bins strategically positioned to divert thousands of pounds of clean medical plastic into recycling streams. The result was a 50% reduction in disposal costs, accompanied by a significant decrease in environmental impact. Similarly, pilot programs have shown impressive success in specific applications. One UK hospital switched to reusable sharps containers made of durable plastic that can be sterilized and reused hundreds of times, eliminating 15 tons of disposable plastic sharps containers in a single year while slashing sharps waste carbon emissions by 87% through avoided manufacturing and disposal.

On a larger scale, healthcare systems and plastic producers are collaborating on recycling pilot programs that create infrastructure and end markets for difficult-to-recycle medical plastics. These initiatives collect materials like Tyvek packaging, PVC privacy curtains, or polypropylene gowns and channel them to specialized recyclers who can process them into new products. These partnerships are creating new markets for recycled medical plastics and demonstrating technical and economic feasibility.

Checklist: Best Practices for Plastic Recycling

Audit your waste: Conduct regular, comprehensive waste audits to measure disposal volumes against recycling volumes and understand the composition of your waste. Knowing which departments generate the most plastic, what types predominate, and current contamination rates helps target improvement efforts where they will have the most significant impact. Baseline measurements are essential for tracking progress.

Segregate streams: Place clearly labeled bins for recyclable plastics such as bottles, rigid trays, and clean wraps, separate from biohazard waste and general trash. Color-code containers using standardized colors (blue for recycling, red for biohazard, and black for trash) and label them with both pictures and text to minimize sorting errors. Position recycling bins directly adjacent to trash receptacles to make recycling as convenient as disposing of waste.

Train staff: Educate clinical and janitorial teams comprehensively on the safe recycling of plastics without compromising infection control. Emphasize OSHA-compliant handling of sharps and contaminated materials to ensure that worker safety is never compromised in pursuit of sustainability goals. Training should be hands-on with examples of specific items, ongoing rather than one-time, and reinforced through signage and reminders.

Use reusable containers: Whenever possible and clinically appropriate, switch from single-use disposable items to reusable containers for sharps collection, linen transport, instrument sterilization, and other supplies. Reusable products dramatically reduce plastic consumption and waste generation while often providing superior performance. The initial investment in reusable containers is typically recovered within months through avoided disposal costs.

Partner with a certified hauler: Work with a licensed medical waste company that offers both secure waste removal and recycling pickup services. Ensure they follow OSHA guidelines, including bloodborne pathogen standards and personal protective equipment requirements, to maintain worker safety, and can provide documentation of proper handling procedures. A qualified partner can navigate the complex regulations and logistics of healthcare waste while supporting sustainability goals.

HIPAA-compliant shredding: Shred any paper protected health information (PHI) or related media before disposal, and ensure electronic devices are properly sanitized. Services with NAID (National Association for Information Destruction) certification ensure secure shredding that meets legal standards, supporting HIPAA and other privacy regulations, while facilitating the recycling of shredded paper. Never compromise patient privacy for environmental goals.

Measure and improve: Track progress through key performance indicators such as pounds recycled versus disposed, recycling rate as a percentage of total waste, cost savings from reduced disposal, and contamination rates. Adjust practices based on data, celebrate successes to maintain momentum, and implement continuous improvement processes to meet increasingly ambitious sustainability goals over time.

Expert Tip:

Start small and scale up gradually to ensure success. Experts consistently recommend piloting a recycling program in a high-impact area, such as an operating room, intensive care unit, or clinical laboratory, before attempting a hospital-wide implementation. This focused approach allows you to fine-tune sorting procedures, optimize collection logistics, test staff education approaches, and identify unforeseen challenges in a controlled environment. Once a pilot demonstrates success through measurable metrics, such as high participation rates and low contamination, expand gradually to other departments by applying the lessons learned, rather than implementing everywhere simultaneously and risking failure.

Regulatory & Compliance Considerations

All recycling initiatives must comply fully with healthcare regulations without exception, as sustainability cannot come at the expense of safety or legal compliance. OSHA requires that workers handling medical waste be protected under the Bloodborne Pathogens standard through the use of engineering controls, work practice controls, appropriate personal protective equipment (PPE), and comprehensive training. This applies equally to waste destined for recycling and waste being disposed of. Workers sorting recyclables must have access to gloves, hand hygiene facilities, and training on the risks of contamination.

HIPAA requires that any patient-related data, images, or specimens in waste be securely destroyed to prevent unauthorized access to protected health information. Using NAID-accredited shredding services and confidential destruction vendors ensures HIPAA compliance when disposing of paperwork, patient labels, prescription information, or sensitive materials. Certificates of destruction provide documentation that PHI was handled correctly. By combining these essential compliance measures with sustainability initiatives, facilities can implement truly secure waste removal, ensuring all waste is dealt with safely, legally, and in an environmentally responsible manner without compromising any requirements.

Conclusion

Recycling plastics in healthcare settings is a crucial component of modern medical waste disposal strategies and represents a significant opportunity for both environmental and economic benefits. By adopting sustainable waste practices, including segregating recyclable plastics at the point of generation, using reusable containers to prevent waste, and working with compliant disposal partners who understand healthcare regulations, facilities can simultaneously reduce costs, meet OSHA and HIPAA requirements without compromise, and lessen environmental impact through decreased landfill use and greenhouse gas emissions.

Secure Waste is ready to help your facility implement these comprehensive solutions with expertise in both compliance and sustainability. For expert guidance on compliant medical waste disposal and sustainable recycling programs tailored to your facility’s unique needs and waste streams, contact Secure Waste and request a free assessment today to begin your sustainability journey.

Expert Medical Waste Management: With over 25 years of industry experience, Secure Waste is a trusted local leader in hazardous and biohazardous waste disposal across Maryland, Virginia, and Washington, D.C. Specializing in medical waste management, sharps needle disposal, and biohazard waste removal, the company ensures full compliance with federal, state, and local regulations while prioritizing environmental sustainability.

The company also offers additional services, including secure document shredding and sharps container sales, providing comprehensive solutions for healthcare facilities and businesses. Our cost-effective services help clients maintain regulatory compliance without unexpected costs.

With a commitment to customer satisfaction, Secure Waste offers tailored waste management plans that align with industry best practices. Their team of experts provides reliable, timely, and compliant services, making them the preferred choice for medical waste disposal. For a free waste quote or more information, visit www.securewaste.net